ADVICE AND SERVICE

Our highly-skilled colorists are there to provide advice for the execution of your project.

The close contact between the sales representatives and our development department and the long-standing exchange of experience with our customers makes our team the ideal point of contact for you. In order to implement the required specifications and wishes of our customers quickly and purposefully, we foster a close and cooperative collaboration with them during the development phase.

Our highly-skilled colorists are there to provide advice for the execution of your project.

The close contact between the sales representatives and our development department and the long-standing exchange of experience with our customers makes our team the ideal point of contact for you. In order to implement the required specifications and wishes of our customers quickly and purposefully, we foster a close and cooperative collaboration with them during the development phase.

PRODUCT SAFETY – You’re safe with us

We will of course make the relevant safety information sheets available on request.

Top level quality

For many years we have worked with a quality management system, certified according to the DIN EN ISO 9001 standard, in order to satisfy the high standards of quality of our customers.

The manufacturing and development of our color concentrates is carried out under strict quality controls, which are carried out in our laboratory by trained employees according to specified testing instructions. Each employee is obliged to self-regulation in order to recognize any possible errors as early as possible and take the necessary action.

%

Our goal is our “Zero-Error-Strategy“

Only products that meet the defined quality criteria exactly leave our factory. We regularly test our processes in order to improve the quality of our products and eliminate any possible sources of errors. Works test certificates and colorimetric protocols document our quality.

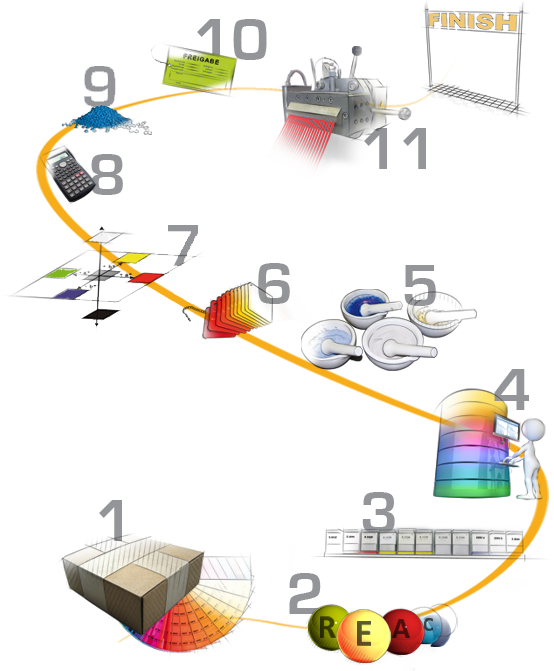

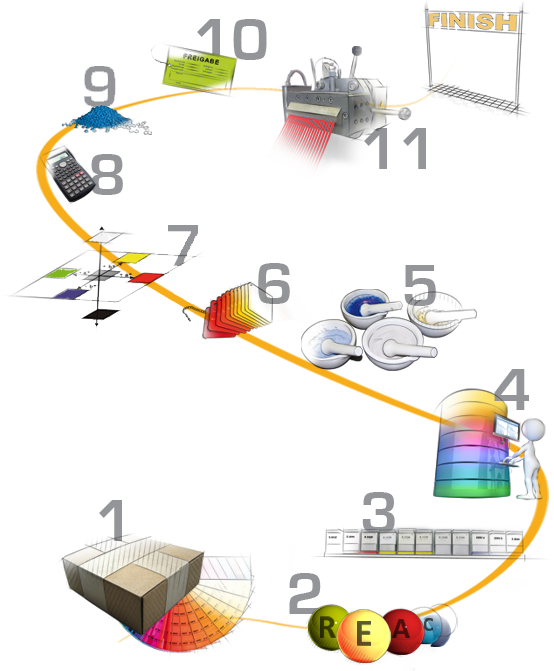

Development process

Going from the development to the production of our color concentrates is a long and labor-intensive process. The following process chain illustrates the 11 steps of the development work of our colorists.

Our customer sends us a color sample or gives us a color code from a known color system, e.g. RAL, NCS, Pantone.

The customer is asked to provide a precise specification, e.g. type of plastic, light and temperature resistance, regulations and guidelines to be met, intended purpose, treatment process.

According to the provided specifications, the raw materials that can be used for the development of the color are determined.

The suitable shade will be searched for in the formula database – which contains over 80,000 formulations.

If no suitable color formula is found in the database, then a new, tailor-made shade is developed in the laboratory.

Production of test plates in the customer’s raw material so that the intrinsic color of the polymer can be taken into account, as this is sometimes very strong.

Target-actual analyses of the customer’s specification of the new color formula. If it is a positive result then the formula is approved.

Only when the new color formula is approved can the offer price be calculated.

Production of sample from the laboratory mixer/extruder for the customer to carry out their first tests under their own operating conditions.

After successful customer tests we receive the approval. The color formula is approved for a possible order.

We look forward to receiving your orders!

Online Service

Here you can find information on different subjects available to download.